April 8, 2019 - A new case study written with Desktop Metal has been published. Despite its young age, Desktop Metal is making waves in the 3D printing industry. The company was founded in October 2015 by an all-star team of 3D printing experts with a common goal—making metal 3D printing more accessible by tackling the challenges in this area, including cost, quality, speed and safety.... In order to inspect and verify 3D printed parts, Desktop Metal needed a metrology solution as advanced as its technology. And with a broad customer base, Desktop Metal needed to be able to measure parts from multiple disciplines across the manufacturing industry—including aerospace, medical, automotive, and more. In addition, 3D printing is often used to create complex shapes and geometries unattainable with traditional metal manufacturing methods, so Desktop Metal needed to be able to measure these kinds of parts accurately as well.

Despite its young age, Desktop Metal is making waves in the 3D printing industry. The company was founded in October 2015 by an all-star team of 3D printing experts with a common goal—making metal 3D printing more accessible by tackling the challenges in this area, including cost, quality, speed and safety.... In order to inspect and verify 3D printed parts, Desktop Metal needed a metrology solution as advanced as its technology. And with a broad customer base, Desktop Metal needed to be able to measure parts from multiple disciplines across the manufacturing industry—including aerospace, medical, automotive, and more. In addition, 3D printing is often used to create complex shapes and geometries unattainable with traditional metal manufacturing methods, so Desktop Metal needed to be able to measure these kinds of parts accurately as well.

October 17, 2019

Capture 3D, Inc.

23070 Commerce Drive

Farmington Hills, MI 48335

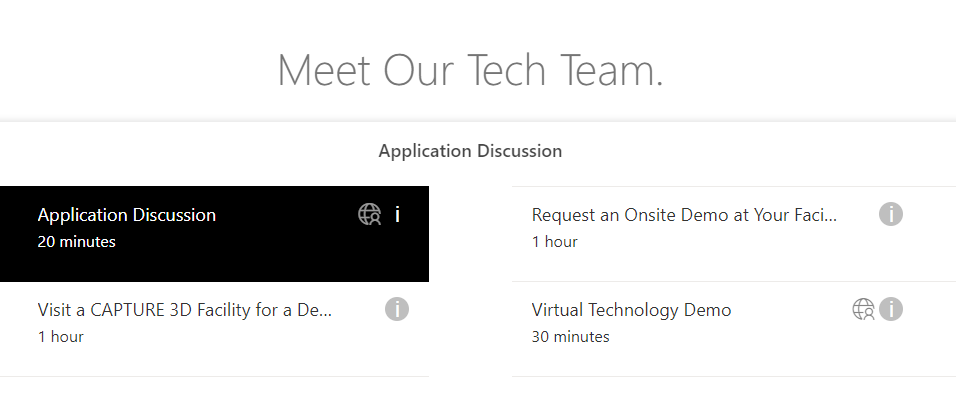

Schedule time with us.

During our time together you'll learn:

- Configuration and pricing options for your application, needs, and budget.

- Discuss the capabilities and real-engineering case studies.

- See how 3D scanning works in real-time and learn why data quality matters.

- Actual scan data compared to CAD/drawings with color-map comparisons

- CMM-type data reports, and advanced dimensional analysis features.

Talk about what is important to you and have this meeting custom-tailored to answer your questions.

Click here to schedule!

July 11, 2019

9AM to 3:30PM

Four Points by Sheraton

9461 Roosevelt Blvd.

Philadelphia, PA 19114

*In conjunction with Rethink Plastics Knowledge Day. Breakfast and lunch will be provided.

This special self-evaporating 3D scanning spray formula was developed by engineers to help 3D scan reflective, transparent and difficult surfaces.

If you're in the market for a blue light 3D scanner, you probably already know that they reduce costs and improve reverse engineering and inspection processes; however, you may also be considering a handheld 3D scanning solution. With their extreme portability, handheld 3D scanners have become a popular choice, but how do you know if they're the right choice for your reverse engineering project? Keep reading to find out!

Blue light 3D scanners make 3D printing and prototyping more efficient and helps streamline workflows. Using blue light technology, a narrow band of LED blue light prevents interferences from outside light and refracted light. This enables precise data collection that results in an accurate digital twin.

Handheld 3D scanners are portable devices much the same as ATOS blue light non-mobile scanners that conduct scans quickly and use optical non-contact technology to get high-resolution images at incredibly high speeds.

3D scanning is changing the landscape of a number of modern industries. Manufacturing, construction, aviation, aerospace, oil refineries, and a number of other verticals have leveraged 3D scanning with great success and adoption across other industries continues to grow. In fact, IDC projects that shipments of 3D scanners will experience an 18% CAGR (compound annual growth rate) between 2018-2022.